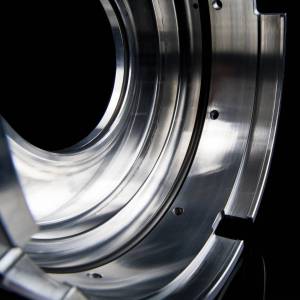

SUNCOAST 68RFE SC-961 JR BILLET DRUM W/INTER

Description

Key Features include:

SunCoast's Dodge series rebuild kits cover all years from 2007.5/2016 (kit part number dependent upon year/parts required). These kits utilize the latest proven friction materials and steel technology from industry leading companies such as Alto and Raybestos. SunCoast works directly with these companies to design and manufacture proprietary exclusive SunCoast product lines, giving the end user uncompromised quality throughout the entire transmission. SunCoast has designed these kits in house to exact specifications for many intents, including but not limited to towing, sled pulling, racing or having a vehicle to get from point A to point B. Along with these kits, SunCoast has a full line of billet single/triple disc torque converters ranging from 1800 stall to approximately 3000 RPM (manufactured in house). In addition the company has multiple Billet input shafts, oversized/stock aluminum drums (M3gaa Drum & JR drum) )SFI approved flex plates, SFI approved transmission jackets, and much more.

The SunCoast M3GA JR. kit is a perfect solution for a deleted, mildly modified truck that can serve as a dual purpose unit. The transmission is a workhorse. It works incredibly well as a towing unit for hot-shot driving, 5th wheel motorhomes, and most anything else you can hook up to the back end. When coupled with one of our towing triple disc billet torque converters, you will not find a more efficient transmission on the planet at any cost.

This kit is also capable of a mildly modified street performance machine. This base package is good for up to 600hp with the addition of a few key hard parts, such as the billet flexplate and billet input shaft, which is highly recommended.The M3GA JR 68RFE unit is specifically designed to eliminate the dreaded overdrive issues. We started researching this project with a clean slate. There are several key issues with the 68RFE that contribute to the pre-mature failure of the overdrive clutches.

The Beat Of A Different Drum . . .

The 68RFE is known to be plagued with a number of issues during its life behind the 6.7L Cummins power plant. The torque the power plants produce wreaks havoc on everything it comes in contact with. Throw in some bigger wheels and tires, increase reciprocating mass and delete torque management it is now wonder the 68RFE is writing suicide notes and leaving them in your mailbox.

The most problematic area is the overdrive/underdrive clutch circuit. After correcting the pressure issues we then knew we needed to take a long look at the clutches and what could be done to tame these nasty demons.

The rule around here is when we are evaluating issues is that we strive to take a scientific approach to the problem. When we are talking science, we know that doesn't lie. Well if math doesn't lie we knew fairly quickly where the problem stemmed.

In testing we found that with the newly found pressure, we were still falling short. The factory drum at 200 psi of line pressure netted us a 4479lbs of clamping load. While this is a dramatic improvement over the factory piece this did fall short of our goals. We knew from previous testing that more clamping force would be needed to ensure that we needed more, a good bit more. One of the obstacles was the design of the drum and the piston that the factory left us with. Conventional logic would tell us that we should just drive line pressure until we achieved the desired clamping force. After doing some quick math it became apparent that the pump would need to deliver in excess of 350psi, which was well in excess of the current pumps ability.

SunCoast decided early that we needed to develop an new drum. When designing the drum we were able to change the piston apply area giving us a nice boost in clamping force. SunCoast also the decided to make the apply piston larger increasing the size of the drum as well. Increasing the size of the drum and piston netted us a clamping force of a whopping 6909psi at 200 psi of line pressure. When comparing to the factory drums 4479 psi, we saw a dramatic improvement over the factory. With the larger drum we were able to also increase the size of the clutch.

The SunCoast M3GA drum boast a 51% increase in surface apply area versus the competition. SunCoast has also achieved a 54% increase in hydraulic apply area. This billet drum is manufactured in house using T-6061 billet aircraft grade aluminum. This new drum is the perfect solution for a heavily modified 6.7 power plant.

- - Custom Tuning Heavily recommended

Details

- 68-961JR

- 68-961JR

- SunCoast Diesel

- New

Categories

Shipping Information

- Item Requires Shipping

- 7.0 lbs.

- Free ground shipping for all orders over $150 lower 48 states

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!