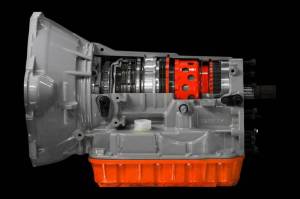

SUNCOAST 68RFE 4WD M3GA COMPETITION AUTOMATIC TRANSMISSION

Description

Key Features of this SunCoast Custom Build include:

- SunCoast Custom Patented M3GA full comp billet drum

- SunCoast Custom Calibrated valve body

- SunCoast Custom Calibrated pump

- SunCoast Custom TC limit Valve modification

- SunCoast Custom water jetted seperator plate

- SunCoast Custom machined Billet Overdrive Accumalator piston

- SunCoast Custom machined billet apply plate

- SunCoast Custom designed 2C apply plate

- SunCoast Custom designed 2C powerpack

- SunCoast Custom designed clutch stack ups for all other clutch packs

- SunCoast Custom designed overdrive/ underdrive powerpack

- SunCoast Custom patented Billet L/R Sprag

- SunCoast Custom Billet C2 Piston

- SunCoast Custom Billet C4 spring retainer

- New Bushings

- New Torrington Thrust Bearings

- New Thrust Washers

This unit is also capable of a mildly modified street performance machine. This base package is good for up to 600hp with the addition of a few key hard parts, such as the billet flexplate and billet input shaft, which is highly recommended.The M3GA JR 68RFE unit is specifically designed to eliminate the dreaded overdrive issues. We started researching this project with a clean slate. There are several key issues with the 68RFE that contribute to the pre-mature failure of the overdrive clutches.

The 68RFE pump was the first problematic area that we addressed. Our engineers were able to determine the amount of clamping force needed to make the clutches hold. Unfortunately, the factory configuration is not capable of achieving this. Let's take a quick look at some key issues addressed:

Line Pressure:

The factory pump is not capable of producing enough line pressure, and it somehow bleeds off in all forward gears. SunCoast corrects this by modifying the factory pump to not only allow it to achieve "said" needed line pressure, but keep it from bleeding off as well. All of our 68RFE pumps are vacuum tested to verify that we have absolutely no cross leaks. Additionally, SunCoast has a custom PR valve that is inside the pump that we modify to help us reliably achieve needed line pressure. SunCoast also addresses the issue with the ballooning torque converter by revising the TC circuit and repairing the drain back issues that causes this. SunCoast has also redesigned the spring and recalibrated it for our specific needs. This circuit also receives a redesigned valve. SunCoast has also completely redesigned the separator plate. This separator plate is custom laser cut to ensure precision, accuracy, and of course, consistency. This new separator plate is very different from the factory, and it allows SunCoast to manipulate the oncoming and off-going clutch timing with pinpoint precision. This new SunCoast designed separator plate is also made from a higher grade of aluminum to ensure flexing and deflection do not occur.

Flipping out over the sprag:

The factory Low/Reverse sprag assembly has been a sore spot for many customers after a nasty boosted launch. It has left many of the 68RFE's stranded on the side of the road with a fat taste of disappointment in their mouth. The issue with this factory unit is inherent to the design. The factory unit utilizes a "dogbone" type sprag. The 68RFE Low/Reverse clutch is only on when the output shaft is turning below 150 rpm's. These Low/Reverse clutches then release the load back onto the factory Low/Reverse sprag, which during heavy acceleration, boosted launches, and burnouts will not stand up to such stress. The result will be the loss of first and second gear starts. The phrase "Copied but never caught", has been a phrase we have thrown around for years here, yet again we bring you another example.

When SunCoast first saw this, we knew immediately this would not be acceptable for our torque-hungry clients, and so we went to work. SunCoast knew that the sprag had to be pre-loaded with tension and the old "dogbone" style was not going to work. Hence, our very first design was to switch to an accordian style of spring. This proved to not only provided a sufficient amount of tension to keep the sprag from flipping, but held at the current power levels we were seeing at the time. As with anything we see, we knew it was only a matter of time before we would see the limits being pushed with our new design. Fast forward to 8 years later, and now this design has been copied and almost every retailer is selling their version of this design. The unfortunate aspect of this is that this design has reached its capacity with the power levels being reached in the new 6.7 Cummins, and we are seeing even the new design achieve catastrophic failure. However, we already were aware of this potential failure and have been hard at work with the patent office yet again. In all of our 68RFE units we now include our new Patent-Pending Billet M3GA sprag. This is an all-billet design, not the plastic stuff the competition wants to sell you. SunCoasts all-billet M3GA Sprag also includes a redesigned spring style to ensure the preload is sufficient to alleviate the problems. This new billet design is absolutely unbreakable and currently has a Patent Pending. Plastic or Billet? We will let you decide.

The Valve Body:

The valve body is like the brain of the transmission. It is the single most important item in the transmission. Here at SunCoast, we take a very scientific approach to how we calibrate these units. We start with addressing the accumulator cover plate. It has been shown time and time again that these factory side plates are prone to deflection due to the fact they are made with inferior steel, and a bit thinner than desired. If you start driving line pressure even higher, you will see this issue with deflection become even more prevalent. When this deflection occurs, it often times will cause the screws to loosen, and in some instances even break. SunCoast replaces the factory plate with a thicker, reinforced plate that adds 3 additional holes to allow for additional, stronger mounting screws to keep flex to a minimum. This new accumulator cover plate is standard on all SunCoast 68RFE builds.

SunCoast continues the improvements on the valve body circuit by replacing each solenoid pack with a brand new factory OE Mopar solenoid pack. This may be incredibly expensive, but we feel it is an absolute must. While the reasons may be obvious to some, allow me to explain it to you. Every other builder either uses the factory solenoid pack again, or a remanufactured one. Here at SunCoast, this is unacceptable and here is why: It is well documented that the solenoid pack has numerous fail issues. If you have a core that you are building from, more than likely it is there as a core because it failed. When failure occurs, debris, in the way of metals, clutch material, and other contaminants are circulated throughout the transmission. That debris is almost certain to have made its way into the solenoids. This contamination in the solenoids now remains there. So now we take this new, freshly built transmission and introduce the contaminants from the failure into our new unit. Those contaminants can, and will, affect the spray pattern and flow of these solenoids. In the early days, we took the liberty of purchasing a solenoid flow tester to verify the integrity of these solenoids. What we found is that the failure rate was in excess of 60% due to contaminants. Of that 60%, about 10% could be run through the flow tester with a special solvent to clean them enough to restore the spray pattern and flow rate. Our competition may make the argument that they spent the $10,000 + to check and verify these solenoids and clean them, but the only issue with this is that you are still going to have a significant failure rate. SunCoast, as well as Chrysler, has documented that the factory boards on these solenoid packs flex, causing false pressure switch codes. So even if you spent the 5+ hours to restore the flow rate and spray pattern you still have a fatigued board. This could very well cause false codes and drivability issues. SunCoast corrects this by throwing the factory solenoid pack in the trash and replacing it with a new factory unit from Mopar. SunCoast also installs a custom made solenoid spacer-block to correct the flexing issue. Some may tell you that this is overkill, and uneccassary, but we believe it is our duty to ensure that our customers get exactly what they deserve. No corners cut, no shortcuts taken.

Another area of concern in the factory valve body is the issue with the factory solenoid switch valve. These factory pieces allow cross-leaking and continually cause burnt 4C and Overdrive clutches. Very often, it causes the plugs to cock and hang up in the bore. This will result in a failsafe (limp mode), various codes, bind-ups, and burnt TCC clutches. Customers will often complain of the engine stalling, or loss of fuel economy, due to no lock-up. On every one of our SunCoast valve bodies we correct this by replacing the factory solenoid switch valve with a new, custom designed valve made with annular grooves to help center the valve and plugs in the bore to prevent future side-load wear. This special valve is also hard-coat anodized to prevent premature wear. We also have special o-ringed end bore plugs that have been redesigned to ensure cocking can no longer occur. Finally, the next problematic area we correct is the issue with the factory Overdrive/Underdrive accumulator piston. You will see others attempting to shim these accumulators, trying to correct stroke issues, and they use recalibrated springs to correct the cold driving 1-2 shudder, excessive CVI's, slide shift, etc. The fact that it is plastic doesn't help either. There are companies even making sleeves to try and attempt to fix the bore cross leaking. Our fix is to redesign it. SunCoast uses a custom billet accumulator piston with additional sealing rings, made in-house. This new custom billet overdrive/underdrive piston not only corrects cross-leaking, but it also changes the stroke of the accumulator, allowing much quicker shifts than could be achieved otherwise. This also extends the life of the overdrive/underdrive clutches. Is a billet, custom cnc'd accumulator piston really needed? Well if youre SunCoast, the answer is obvious and it is in every one of our valve bodies. What does your builder do?

The Beat Of A Different Drum . . .

The 68RFE is known to be plagued with a number of issues during its life behind the 6.7L Cummins power plant. The torque the power plants produce wreaks havoc on everything it comes in contact with. Throw in some bigger wheels and tires, increase reciprocating mass and delete torque management it is now wonder the 68RFE is writing suicide notes and leaving them in your mailbox.

The most problematic area is the overdrive/underdrive clutch circuit. After correcting the pressure issues we then knew we needed to take a long look at the clutches and what could be done to tame these nasty demons.

The rule around here is when we are evaluating issues is that we strive to take a scientific approach to the problem. When we are talking science, we know that doesn't lie. Well if math doesn't lie we knew fairly quickly where the problem stemmed.

In testing we found that with the newly found pressure, we were still falling short. The factory drum at 200 psi of line pressure netted us a 4479lbs of clamping load. While this is a dramatic improvement over the factory piece this did fall short of our goals. We knew from previous testing that more clamping force would be needed to ensure that we needed more, a good bit more. One of the obstacles was the design of the drum and the piston that the factory left us with. Conventional logic would tell us that we should just drive line pressure until we achieved the desired clamping force. After doing some quick math it became apparent that the pump would need to deliver in excess of 350psi, which was well in excess of the current pumps ability.

SunCoast decided early that we needed to develop an new drum. When designing the drum we were able to change the piston apply area giving us a nice boost in clamping force. SunCoast also the decided to make the apply piston larger increasing the size of the drum as well. Increasing the size of the drum and piston netted us a clamping force of a whopping 6909psi at 200 psi of line pressure. When comparing to the factory drums 4479 psi, we saw a dramatic improvement over the factory. With the larger drum we were able to also increase the size of the clutch.

The SunCoast M3GA drum boast a 51% increase in surface apply area versus the competition. SunCoast has also achieved a 54% increase in hydraulic apply area. This billet drum is manufactured in house using T-6061 billet aircraft grade aluminum. This new drum is the perfect solution for a heavily modified 6.7 power plant.

- - Custom Tuning Heavily recommended for the transmission.

- - All Competition units carry a 12 month unlimited mileage warranty

- TORQUE CONVERTER SOLD SEPERATELY.

Details

- PLSD-68RFE-M3GA-4X

- PLSD-68RFE-M3GA-4X

- SunCoast Diesel

- New

Shipping Information

- Item Requires Shipping

- 350.0 lbs.

- W36.0000” x H28.0000” x L36.0000”

- This item will require a special quote for shipping charges.

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!